Magnesium Oxide (MGO) boards have rapidly emerged as a leading alternative to traditional drywall and cement board, offering builders, architects, and homeowners a versatile, durable, and eco-friendly solution for both interior and exterior applications. Here’s why MGO boards are transforming modern construction.

What Are MGO Boards?

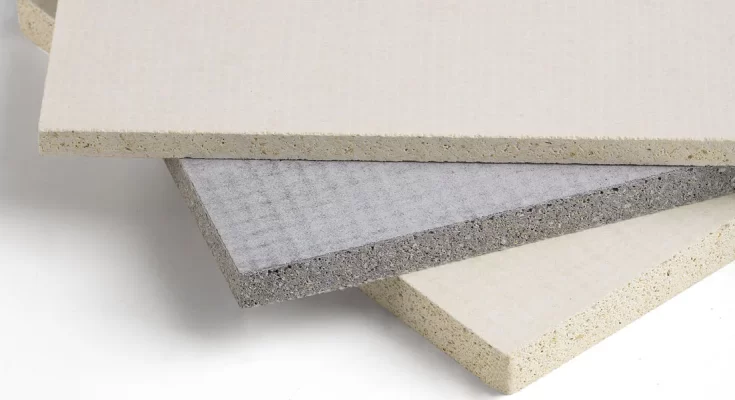

MGO boards, also known as magnesium oxide boards, are engineered panels composed primarily of magnesium oxide, magnesium chloride, and reinforcing fibers. This unique combination yields a lightweight yet exceptionally strong product that resists fire, moisture, mold, and impact far better than gypsum drywall or conventional cement boards.

Key Advantages

1. Fire Resistance

Unlike standard gypsum boards, MGO boards can withstand temperatures up to 1,200 °C (2,192 °F) without structural degradation, making them ideal for high-risk zones and passive fire protection systems.

2. Moisture and Mold Resistance

The hydrophobic nature of magnesium oxide prevents water absorption and mold growth, ensuring long-term performance in bathrooms, kitchens, basements, and exterior cladding.

3. Impact and Wear Durability

With a surface hardness comparable to cement board but at a fraction of the weight, MGO panels sustain heavy daily wear—perfect for commercial spaces, schools, and hospitals.

4. Eco-Friendliness

MGO boards are manufactured using low-energy processes and natural minerals. They contain no asbestos, formaldehyde, or other harmful VOCs, contributing to healthier indoor air quality and reduced environmental impact.

Common Applications

Interior Walls & Ceilings: Seamless finish for living rooms, bathrooms, and corridors.

Exterior Cladding: Weatherproof facades and soffits.

Floor Underlayment: Stable base for tile, wood, or vinyl flooring.

Fire-Rated Assemblies: Firewalls, shafts, and stairwells requiring stringent safety standards.

Acoustic Panels: Noise-reducing partitions in theaters, studios, and open-plan offices.

Installation Tips

Cutting & Handling: Score and snap with standard drywall tools. Wear a dust mask to minimize inhalation of fine particulates.

Fastening: Use corrosion-resistant screws placed at 150 mm (6 “) centers along edges and 200 mm (8 “) in the field.

Joint Treatment: Fill seams with a compatible MGO joint compound; embed fiberglass tape and apply two finish coats.

Finishing: Sand lightly once cured; paint or tile directly without additional primers.

Choosing the Right MGO Board

When selecting MGO boards, consider thickness (commonly 6–20 mm), density, and reinforcement type (glass fiber vs. wood fiber) based on structural requirements and desired finish. Always verify board certifications—look for EN 12467 compliance in Europe or ASTM C1325 in North America.

MGO boards offer a compelling combination of safety, durability, and sustainability that outperforms many traditional building materials. Whether undertaking a new residential build, a commercial retrofit, or a fire-rated installation, incorporating MGO technology can enhance performance while aligning with green-building goals.

Embrace the future of construction—discover the benefits of MGO boards for your next project.